Now it’s been more than 50 years since I was tasked into working in the tomatoes – or ‘maters as my childhood friends will say back in Bradley County.

But each of us, whether there now or a thousand miles away at other work – can and will attest that the work in the tomato fields sure left a mark on us – be it our physical self or our mental psyche.

Now it’s the time of year, way back when the tomato farmer would be “framing up a cold frame.”

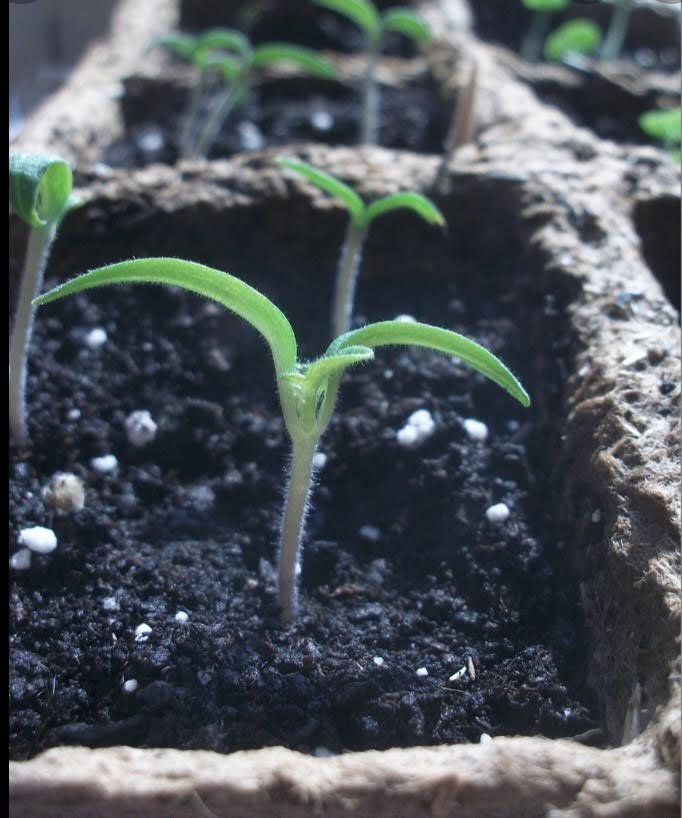

The “cold frame” was a wooden box like contraption affixed on the ground – literally on the cold ground – to help start the seed germination and seedling growing of the future tomato crop. These crude seed plots were usually one-by-six boards, nailed together sometimes 20-feet long and four-to-six feet wide, then loaded with 3-4 inches planting soil where the tiny tomato seeds were inserted by hand to the growing surface of the cold frame.

And a single tomato seed is not a large seed. A little bigger than the letter “a” in this column.

Once the seeds sprouted, one-to-two inches high, somewhat stable, a very delicate operation of getting these seedlings out of the “cold frame” and into the field began.

It was a delicate dance, involving the weather, the farmer, the cold frame and the prepared field with a whole lot of luck to make it work to perfection.

Growers generally plant 2,600 to 5,800 plants per acre in single rows with 18 to 30 inches between plants in the row on 5.0- to 6.5-foot centers.

A double row of compact tomato varieties also can be planted on each plastic-covered bed (10,000 plants per acre), according to an old brochure I found from the UA Extension Service.

One could expect to produce about 4,000 transplants per ounce of seed with approximately 3 ounces required to produce 10,000 seedlings.

For example, to produce 10 acres of tomatoes with 5,800 plants per acre would require 58,000 transplants and would require about 18 ounces of seed (rounding up to 60,000 plants).

I can remember, the individual farmers would come into the feed store to get these rather large paper/plastic envelopes with seeds from the corporate seed outlets. The envelopes would contain less than 8 ounces of seed and were pretty costly.

And the seeds, very valuable, each and every seed. Some farmers saved their own seed, with mixed results.

Over the years, when many small farmers and the old-style open auction sheds were still in vogue, there was a scandal one or two years, where the seeds were not as promised by the supplier. Many think such events led to the demise of the individual farmers at the tomato market, causing the farmers who did grow tomatoes to grow larger multi-acre plots – rather than the small ½ to 1-acre plots of the era of the infancy of the tomato market.

Those old back-breaking cold frames of that era were trying to get an early start on the crop, but thank goodness, didn’t last long until above ground green houses perked up on most steady tomato farms and that’s where the seedlings took place.

But if you worked most of the day on your hands and knees on the cold frames in early to mid-March, some days it was warm – too warm – and one would roll back the cloth covering, lest the plants get too warm and wilt.

And if the night got too cold and a light rain or frost would cover what was used back then as a muslin-type cloth, the farmer was afraid of a freeze in the cold frame. I know of many farmers that ran long extension cords to these “cold frames” with light bulbs attached to give off some semblance of heat to the very tender plants.

My sainted uncle Lonnie Brown, was an innovator to anything to make growing tomatoes easier, quicker, and better for the farmer. And to prove it many a year, he grew tomatoes right along with the farmers who were his customers as he had his own feed & seed store and later managed the Bradley County Farmers Co-Operative when it was a really growing concern, returning profits to all its investors.

Uncle Lonnie, often enlisted me to help him do some “preseason” innovations to the tomato growing process.

One year, he went down to Florida, on a rare vacation to see some “hot caps” as they were called, that were installed on tomatoes set early in the ground. Uncle Lonnie bought a couple of thousand “hot caps” and tried the innovation in the next growing cycle, but they tend never prospered, but small above ground greenhouses, often with a small wood stove to provide heat – did become a staple in these early cool nights and morning and warmer afternoons of growing tomatoes.

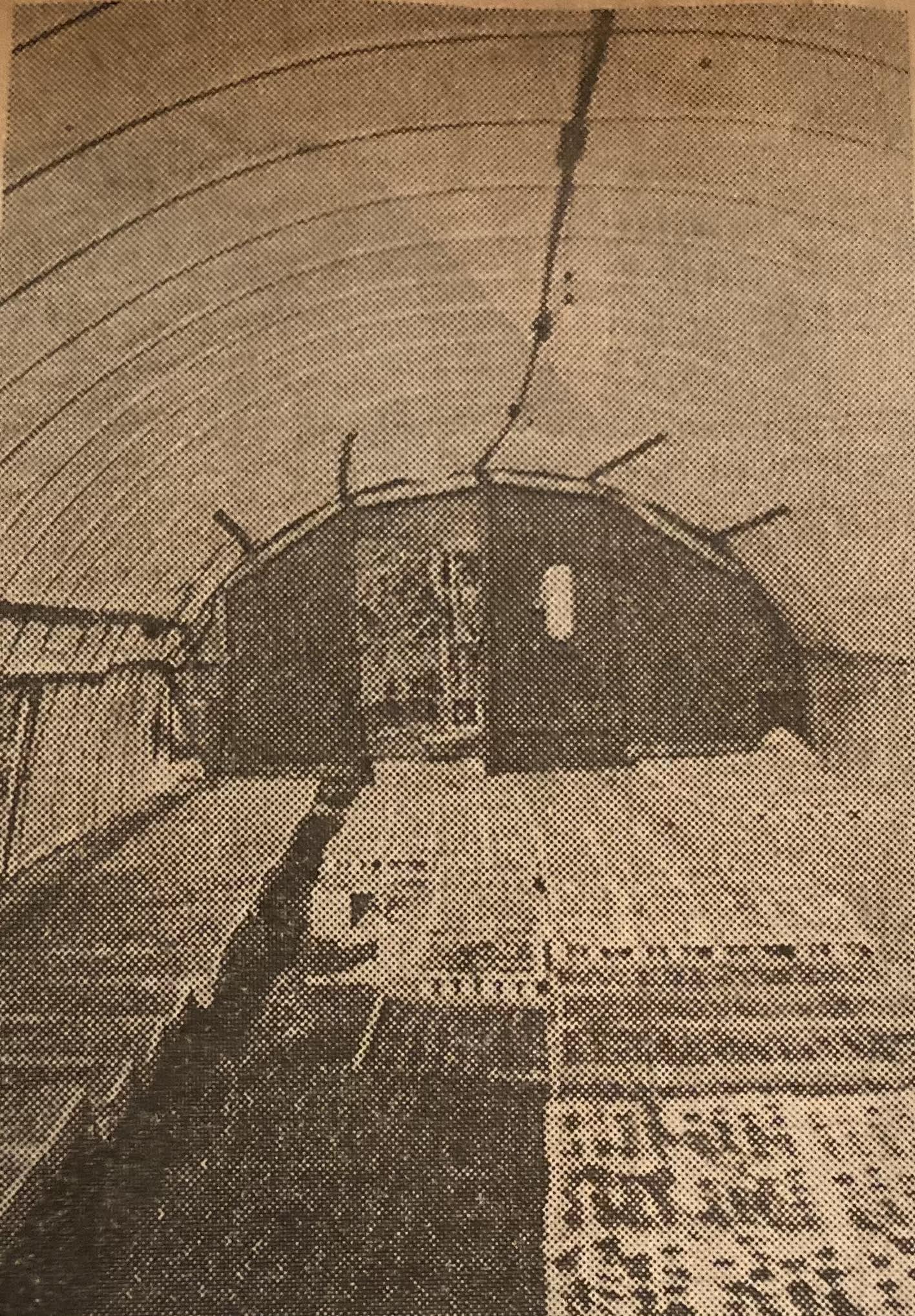

In 1975, he provided some of the technical support for a piece in the Pine Bluff Commercial entitled “Tomato Industry Keeps Up to Date.” Complete with two photos, showing the interior of a plastic Quonset style greenhouse, he told how in a few short years, beginning in 1971, the old “cold frames,” were transitioned to green houses, cutting more than a week to 10-days off the wait to get into the field with new plants.

In that story, some University of Arkansas experts and the local county agents, gave information back when the old wicker tomato baskets went out of use and the new heavy waxed-cardboard boxes were developed.

A year earlier, in 1974, a paper shortage caused the local area markets at Warren and Hermitage, to choose a different supplier of the waxed-heavy cardboard boxes, giving farmers a much flimsier paper box – that did not stack well on the farm and certainly did not hold up to ship the tomatoes via semi to Detroit, Chicago and other nearby produce markets. It was a disaster, but one that was correct, yet cost farmer’s thousands of dollars on that year’s crop.

I grew up near the end of the open tomato market, just before the packing sheds of the “chain” growers began.

I can remember the excitement at the market with pick-up trucks from all over the four-to-five county region backing into the stall at the Warren Auction Market.

I also, like many other kids, worked at night, after the market was closing for the day, helping other guys, like Dr. Kerry Pennington, the Hargis boys, and others load 18-wheelers, with the cooler unit running, for a midnight to early a.m. load out to Joplin, Mo., and then possibly on the Detroit.

There are lots of Pastime memories about the tomato fields and the markets, none more remarkable than those old “cold frames.”